How to Rebuild a Rotted End in an Old Town Otca Wood-Canvas Canoe ̶ Part 2

February 25, 2019

by Mike Elliott, Kettle River Canoes

email: artisan@canoeshop.ca

I started describing the process involved in rebuilding the end of a 1967 18′ Old Town Otca canoe in part 1 of this blog. In it, I described how to replicate the deck. Now, I will describe how to rebuild the stem-top and inwale-ends of this canoe.

Unless the stem-top repair is very short, it will require the use of a new piece of ash that is pre-bent to fit the curve of the original stem. Since you are not replicating the entire stem, the curved section can be created by bending the new ash onto any stem-form. I used a stem-form built to make new stems for a 1905 J.H. Rushton Indian Girl canoe. The 4/4 stock was soaked for four days , steamed for 60 minutes and bent over the form with a backing strip. It was left to dry for a week before removing it from the form.

Hold the newly bent stock up to the OTCA stem and shift it around until you find a section that matches the portion to be repaired. Mark the new stock as well as the point on the inwales where the stem meets them. Cut a scarf joint in the original stem and match the scarf joint in the new ash stock. Use polyurethane glue and clamp the new section of stem into the original overnight.

Use an angle grinder fitted with a 24-grit sanding disk to shape the new section roughly to the dimensions of the original. Leave extra material until you are ready to carve the stem-top to its final dimensions near the end of the project.

Since the inwale-ends have to be pre-bent to match the original curve of the sheer-line, the first step is to build a bending form. Clamp a large piece of cardboard to the sheer-line of the canoe at one end.

Use a permanent ink pen to mark the curve of the sheer-line on the cardboard.

Remove the cardboard from the canoe and cut out the sheer-line profile. You now have a template to transfer onto the bending form stock.

The original curve was increased to compensate for spring-back. Here is the diagram of the bending form used for the OTCA gunwale-ends.

I used two pieces of 2×8 spruce held together with 2½” deck screws to create a 3×8 bending form.

The white oak stock is wide enough to create two bent inwales at the same time. Once the stock is bent, it will be sliced into two inwales on the table saw. Soak the white oak stock for three days and steam it for about 60 minutes. Then, you have about 30 seconds to bent it onto the form. The bend is not large, so a backing strip is not required. Allow the wood to dry in the form for about a week.

Use a flexible straight edge (I use a steel rule) and a permanent ink pen to mark the angle of the scarf joint on the original inwale at a location well into solid wood. Also, mark the point at which the underside of the inwale meets the new stem-top.

Use a saber saw or Japanese cross-cut saw to remove the rotted inwale-end along the scarf angle line.

Smooth the scarf angle with a random-orbital sander set up with 60-grit sandpaper.

Cut the newly bent inwale stock on the table saw to create the desired dimensions for both port and starboard inwales.

Hold the new inwale directly under the original inwale and shift it around until you match the bend. Use a permanent ink pen to mark the location of the scarf joint on the new inwale. Check to make sure the new inwale-end meets the new stem-top in the same place as the original. Use a band saw to cut the scarf angle (other saws can do this job, but the band saw is the safest option and gives the best control).

Dry-fit the new inwale-end and clamp it in place.

Use a flexible straight edge and a permanent ink pen to mark the taper in the inwale-end.

Cut the taper in the new inwale-end on the inside surface of the new stock. Be sure to leave extra material in order to allow for precise fitting later. Then, dry-fit the tapered inwale-end.

Sand the inside surface of the new inwale-end until it is a precise fit. I use a belt sander turned upside down.

Create new inwale-ends for both the port and starboard sides. Use polyurethane glue, clamp them in place and allow them to cure overnight.

The next day, cut the new stem-top to length so it fits snugly under the new inwale-ends. I find it best to cut the stem a little long and sand it gradually (checking frequently) until it fits. Then, sand the sides of the stem until it is flush with the outside surfaces of the new inwale-ends. Again, work gradually and check often.

Dry-fit the new deck and make sure everything is lined up with the centre-line of the canoe. Mark the location of the deck and attach it with 1½” #8 flat-head bronze screws (counter-sunk into the inwales).

Use a random-orbital sander and 60-grit sandpaper to bring the deck flush with the top of the inwales.

Cut the inwale-ends flush with the outside surface of the stem. Then, sand the deck and inwales smooth. Complete the project by staining the new wood to match the orginal.

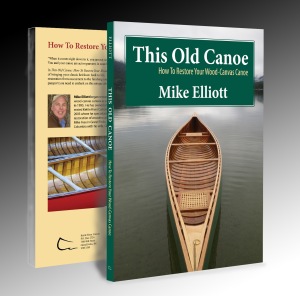

The entire restoration process (including stem-top, inwale-end and deck repairs) is described in my book – This Old Canoe: How To Restore Your Wood Canvas Canoe.

If you live in Canada, CLICK HERE to buy the book.

If you live in the USA, CLICK HERE to buy the book.

If you live in the UK, CLICK HERE to buy the book.

Si vous habitez en France, CLIQUEZ ICI acheter le livre.

If you have read the book, please post a review on Amazon, Goodreads and/or any other review site.